Emsens history

Emsens was founded in 1961 and is specializes in designing and manufacturing machines for the food industry. Located in the Ondaine industrial area (in the Loire district), renowned for its network of metallurgy companies, Emsens has developed expertise that enables it ti meet all the needs of its customers in the food industry.

Today, Emsens is a specialist in design and manufacture of machines for the food industry. The staff of the company includes 19 persons, among which 5 persons at the technical department. It owns several patents and includes a wide distributors network.

The staff of the company includes 19 persons, among which 5 persons at the technical department. It owns several patents and includes a wide distributors network.

Emsens works with local suppliers and partners coming from Rhône-Alpes region at 90% which allows to reduce the logistic and optimize the local know-how in order to get top quality components to produce specific machines on request.

Emsens is locally famous for its high know-how in metallurgy history.

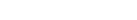

Situated in Fraisses, at the Zone artisanale du Parc, next to Firminy in the Loire district, Emsens offers a wide range of machines for the food industry. With a range including, among others, skewering machines, cutting machines as well as binding machines for salami, Emsens is locally famous for its high know-how in metallurgy history.

Antoine Emsens created Emsens in 1961. The company was first selected as a subcontractor for the CALF (Coal Steel Loire Firminy)

In the eighties, Emsens took the decision to orientate a part of its activity towards the production of its own range of machines for the food industry. At that time, the first successful skewering machines and bacon dicing machines come out of Emsens plant. In the nineties, the technical department was created and the first machines were manufactured from A to Z by Emsens factory. In 2000, Emsens stopped for good to be a subcontractor and dedicated its production to clean machinery. In 2008, the frames of the machines were made in the factory as well which offered a better reactivity and allowed to offer new services in our manufacturing processes.

History

2020

Integration of new technologies adapted to the food-processing industry: machine connectivity and

IO-Link components…

2015

Integration of EHEDG recommendations in the design of new equipments

2010

manufacturing of the frames of the machines at Emsens to optimize the production chain

2000

Emsens stops to be a subcontractor to produce its own products and clean machinery

1990

creation of the technical department to guarantee 100% of the machines designed by Emsens

1980

development of the first skewering and bacon dicing machines

1960-70

metallurgy know-how development– subcontractor of the CALF

1961

creation of the company by Antoine Emsens in Fraisses (Loire-France)