osso bucco

TP

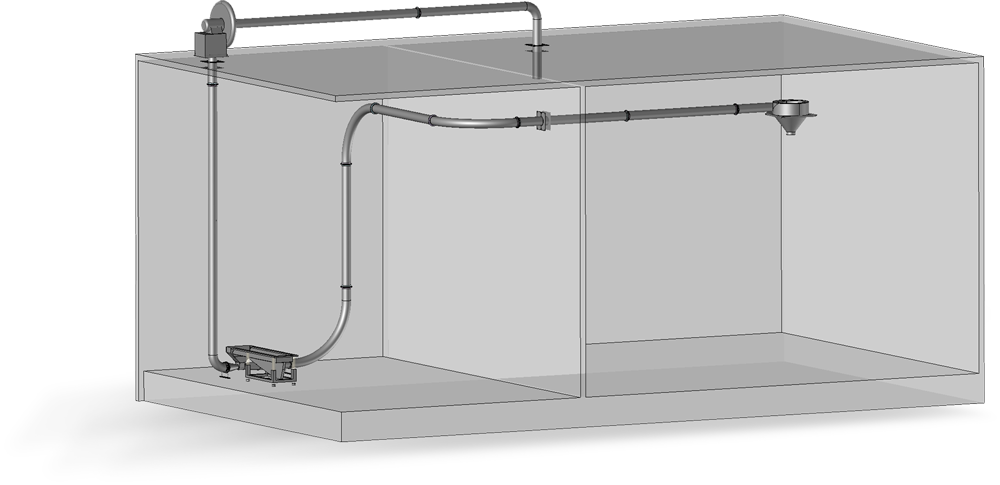

This process allows immediate transfer of food products, for example from a slicer to an associative weigher.

The longest installations carried out are about 25 meters long (between the venturi and the cyclone) including elevation differences of 4 to 5 meters.

This transport system has a fundamental role for process lines requiring high productivity while respecting specific parameters such as hygiene, quality and temperature maintenance of the product.

Elimination of all operating losses

Productivity will depend on the length of the installation and the nature of the products to be transported.

Example: for a lardons cutting line of 8 x 8 mm, the pneumatic transport will allow a rate higher than

2 000 kg/h.

Power: electrical control and electrical power

Materials: stainless steel and polymers

This material is in conformity with the following directives and bills:

Food contact: EC1935/2004

Good manufacturing practice: EC2023/2006

Machines: EC2006/42

CEM: EC 2004/108

TP

advantages

1.

The speed of transfer of the ingredients is an important asset to protect them from bacteriological risks.

2.

Another advantage, it is no longer necessary to manage one or more buffer stocks.

3.

Productivity: Thanks to an immediate transfer, the product maintains its initial temperature thus optimizing the productivity of a weighing line.

4.

Hygiene: Instant product transfer minimizes the risk of pollution and contamination.

5.

The transfer is secure.

6.

External pollution during transport is impossible.

7.

No area may be subject to the development of bacterial pathogens and / or biofilms.

8.

Dimensions: This set will allow you to link efficiency and reliability while preserving a minimum size. Technical solutions allow the pipes to be positioned along walls and/or ceilings.

9.

Cleaning: In order to favor a cleaning procedure, it is important to know the product transported, and its mechanical characteristics.In all cases, there will be no disassembly of the pipes or other elements.

10.

The cleaning is done by injecting water and then foam into the venturi with the full power of the turbine.

11.

For some (fatty) products, we will use a high pressure ferret nozzle in order to have a more suitable mechanical action.

12.

The entire upstream part of the venturi, i.e. the suction mouth passing through the turbine to the venturi, can be cleaned with the same procedure.

13.

The cleaning of the installation is very economical in OM and requires very little water and foam.